Adsorbents - weydaconsulting

Main menu:

Adsorbents

Our Services

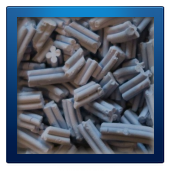

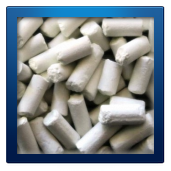

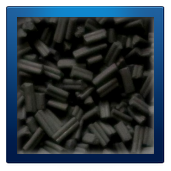

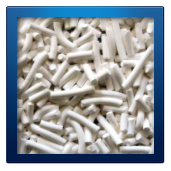

Catalysts in general are applied to convert a particular feedstock into a desired product having a defined product specification. Unfortunately, the feedstock may contain traces of chemical compounds that either negatively impact catalyst activity or selectivity or service life issues. Adsorbents are significantly improving such situation. Adsorbents are also applied in separation proceeses or in bulk chemicals removal, such as dehydration of hydrocarbon streams. Typical examples where adsorbents are installed, are natural gas dehydration units, ethanol dryers, MEDOX generators, refinery reforming units, HF-alkylation plants, VGO-hydrotreaters, VOC-removal for air purification, etc.

weydaconsulting GmbH is granting technical and commercial services for the Chemical Industry with an international focus, in particular advice on catalysts and adsorbents and their applied technologies. Special focus here is in the Oil Refining and Petrochemicals area, plus in automotive emission control and renewables applications as well. All in all, consulting services have been granted to a diverse spectrum of process technologies in petroleum oil refining, lube oil processing, renewable fuels manufacture, gas processing and chemical plants, ... and their related catalyst and adsorbent manufacturing industry. In this frame we completed (or still are working on) a range of client-confidential studies and service activities for our clients in Europe, America and Asia.

- Assistance in procurement of catalysts & adsorbents, zeolites

- Assistance in benchmarking catalysts & adsorbents, zeolites

- Assistance in catalyst, adsorbent and/or process development

- Troubleshooting on technical issues (Performance, Safety, Economics)

- Other 'client-confidential' service activities.

A typical example for applying adsorbents is the reforming process, that involves a precious metal catalyst that may require continuous addition of chlorinated chemicals. Therefore, feedstock needs to be deep hydrodesulphurized to remove bulk sulphur compounds, and prior reforming a sulphur guard is installed to protect the precious metal catalyst from sulphur poisoning. The addition of chlorinated compounds during the reforming process results that HCl or organic chlorides are found in the hydrogen being produced, and to a certain extend also in the liquid product. To avoid corrosion effects and undesired ammonia chloride plugging in the gas stream so-called chloride-guard adsorbents are typically installed.

We work on a global base with our clients on both particular specific short-to-mid term projects, or on long-term consulting service contracts - allowing to support strategies and visions of our clients in a cost effective and efficient approach. Typically, our approach will focus on technical and commercial aspects as well.

Home | About Us | Our Services | Our Client Base | Contact Us | Legal | Impressum | General Site Map